MENU

Peak Galleria, an iconic trademark in Hong Kong, is reopening after a redesign and modernization program for more than two and a half years . The fresh new look is encapsulated by a gleaming, gem-like, curved exterior of the main entrance. The all-glass modernist facade serves as a conduit for natural light into the interior of the mall.

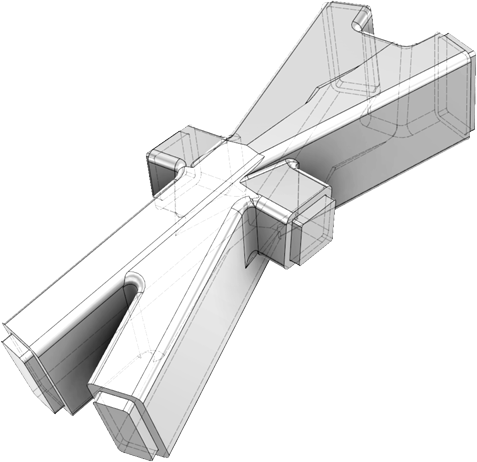

3D Nodes

Assembled Module

Triangular Glass

m2 Facade

135 irregular solid steel star joints (Node)

124 irregular solid aluminum covers

54 sets of assembled modules

8000 plus nos of connection details spreading 5 overlapping construction inter-layers in enlarging curvatures

Traditional welding method is unable to achieve a precise and workable solution to a 3D structure like this. In order to overcome it, we used CNC machining that can produce any 3D shape in terms of micrometre (1/1000 mm) precision and extraordinary touch of finish.

CNC Milling in Action

Star Joint Connections

Every dimension, shape and even the thickness of the protective coating were carefully examined. Each module delivered to site had to be absolutely perfect! Any single mistake would jeopardize the installation as a whole.

within

Days

ASSEMBLY: 135 Star Joints

were connected into 54 assemblies

DISASSEMBLY: The 54 assemblies

were then disassembled after pre-installation

for painting and then packaging for delivery

6 numbers of specific trucks were used to deliver the “tailor-made” modules 24 hours a day and 7 days a week along the tight steep Peak Road in Hong Kong. Thanks to the modern technology, the co-ordination between factory loading and truck arrangement were seamlessly executed with the help of real time GPS monitoring.

The high precision modules reduce the installation time and associated safety issues, accounting for 3-4 modules installation speed a day which is impossible for traditional method.

54 Sets Assembled Modules

237 pcs of irregular

triangular glasses and over 2000m2

of irregular facade and balustrade

glasses

124 irregular solid aluminum covers